MIL-DTL-16356E

4.7.6 Class IV gauge spring cone washer tests.

4.7.6.1 Compression testing. Complete capscrew (bolt) assemblies with assembled spring cone washers in

accordance with 02131 shall be compressed on a tensile test machine or equivalent rigid test frame with hydraulic

actuator. Results must be adjusted to eliminate deflection of the test frame or machine compliance of the tensile

machine. The bolt specimen shall be supported in a hollow coupling so as to permit compression of the washers

without interference from the capscrew portion extending below the washers. A curve of compression load (in

pounds) versus deflection of the washer stack over the range of 0 to 0.040 inch deflection shall be generated. The

stiffness (slope of curve) in the linear region between 0.010 and 0.020 inches of deflection shall be between 110,000

and 225,000 pounds per inch. Variation between samples tested should not exceed 25,000 pounds per inch.

4.7.6.2 Hardness testing of spring cone washers. Rockwell hardness testing shall be conducted on spring cone

washers. A random sample of washers shall be selected from each lot for examination of visual and dimensional

characteristics in accordance with ASQ H1331 at Inspection Level III. Testing shall be done at two locations

180 degrees apart on the internal conical surface, midway between the hole and outer edge. Hardness shall be in

accordance with standard value established during first article test heat treatment testing.

4.7.7 Type A glass sets.

4.7.7.1 First article inspection. The first article sample shall be subjected to the first article inspection shown in

table X.

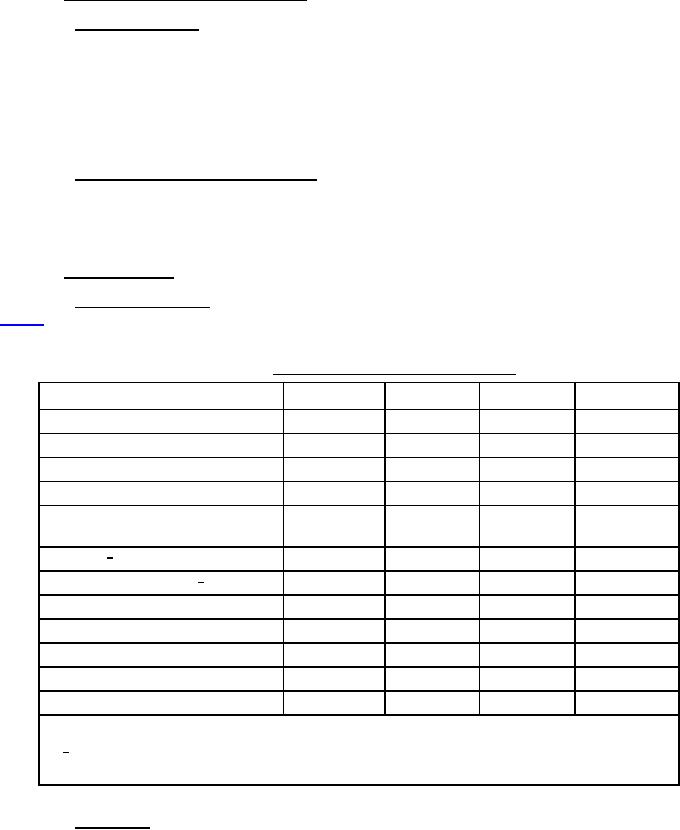

TABLE X. First article and conformance inspection.

Examination and Test

Requirement

Test

First Article

Conformance

General examination

X

X

Visual and dimensional examination

X

X

Thermal shock

X

X

Fracture

X

Simulative service

3.12.3.3 and

X

X

Bend test 1/

X

Polarscopic examination 1/

X

Mica quality

Spring cone washer heat treatment

X

Capscrew spring cone compression

X

Spring cone washer hardness

X

Valve stem hardness

X

X

NOTE:

1/

are not accomplished.

4.7.7.2 Glass set lot. For purposes of sampling, a lot shall consist of all glass sets of one size and type

produced in one plant under the same conditions and offered for delivery at one time. A lot shall not exceed

1000 sets.

27

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business