MIL-DTL-16356E

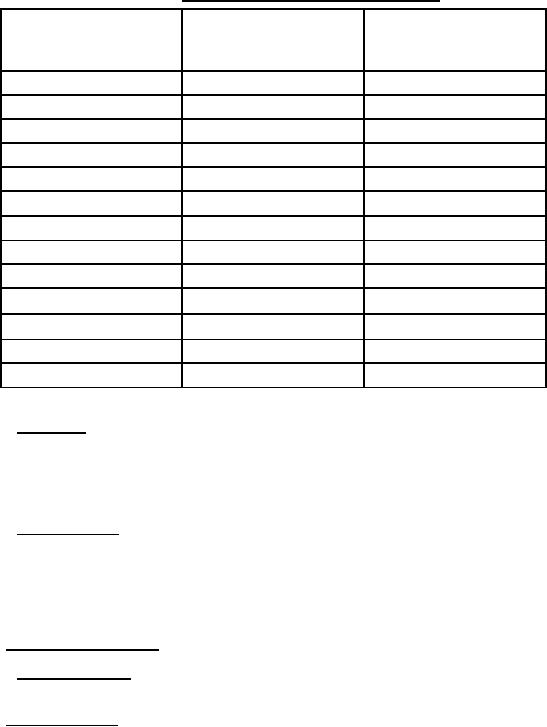

TABLE IV. Sizes (length) of glasses and type I gaskets.

Metric Size

Size

L +0.000 -0.031

L × W × Thick

(Number/Code)

(Inches)

(Millimeters)

0

3¾

-

1

4½

115 × 34 × 17

2

5½

140 × 34 × 17

3

6½

165 × 34 × 17

4

7½

190 × 34 × 17

85/6

5

220 × 34 × 17

9⅞

6

250 × 34 × 17

7

11

280 × 34 × 17

7M

11 (22-degree bevel)

280 × 34 × 17

125/8

8

320 × 34 × 17

133/8

9

340 × 34 × 17

10

14½

370 × 34 × 17

11

15¾

400 × 34 × 17

3.12.3.1.1 Glass faces. The front and back faces of the glasses shall be parallel within 0.004 inch. All

replacement glass supplied under this document shall have a minimum flatness tolerance of 0.002 inch for glass up

to and including Size 3, 0.003 inch for glass Sizes 4 and 5, and 0.005 inch for sizes above Size 5. Glass panes

meeting these requirements should be acceptable for current Navy applications considered High Pressure (HP)

service (see 6.1).

3.12.3.1.2 Glass uniformity. Glass shall contain no scratches or streaks, be uniform in thickness, straight on the

sides, free from twist or warp, and shall be free from irregularities which would cause false indication of water level

meniscus. The glass shall contain no more than 12 air bubbles (inclusions) over all with a maximum bubble

diameter of 0.031 inch, and shall contain no more than six air bubbles within the viewing range of the glass. Air

bubbles shall not be located in any pattern as to cause false indication of water level. No more than three solid

inclusions are permitted per pane, and they shall not be greater than 1/32 inch in diameter.

3.12.3.2 Thermal shock resistance. Glass shall not crack or spall when tested as specified in 4.7.7.5.

3.12.3.2.1 Fracture resistance. Glass shall be tempered so that only an interlocking type fracture shall occur

when tested as specified in 4.7.7.6.

3.12.3.3 Simulative service. Glass shall be smooth and transparent and shall show no erosion of the surfaces

after being subjected to the test specified in 4.7.7.9. Simulative service testing is not required for Class I glass sets

using standard reinforced graphite gaskets installed in gauges with conventional flat gasket seating surfaces. Gauges

using special design seating surfaces (grooved, tapered, curved, or with less than Ra = 400 finish) will require

testing. When simulative service testing is not done, the first article test of 4.7.7.7 and verification test of 4.7.7.8

shall be accomplished on samples of glass from the set.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business