MIL-DTL-16356E

3.12.4.4 Mica shield radius. The radius at the ends of the mica shield shall be accurately die-cut and accurately

faired into the two parallel sides. Each individual piece of the mica shield shall be free of partial films more than

0.0001 inch thick, and only one partial film shall be permitted in each piece. The complete shield shall have only

light visible scratches when hand held at a distance of 6 inches to 1 foot, and only very light visible scratches when

viewed at a distance of 6 feet. Edge fractures resulting from cutting or splitting shall be in accordance with the

following standards:

Applicable thickness of mica shield piece

Extension of edge fractures from edge of piece

Not greater than 1/16 inch

0.004 inch to 0.0075 inch

Not greater than ⅛ inch average of lot samples with

Greater than 0.0075 inch

isolated fractures not greater than 3/16 inch

3.12.5 Gasket.

3.12.5.1 Gasket material. Class I and II steam or water side gaskets shall be made from reinforced flexible

graphite material that conforms to MIL-DTL-24696, Type I.

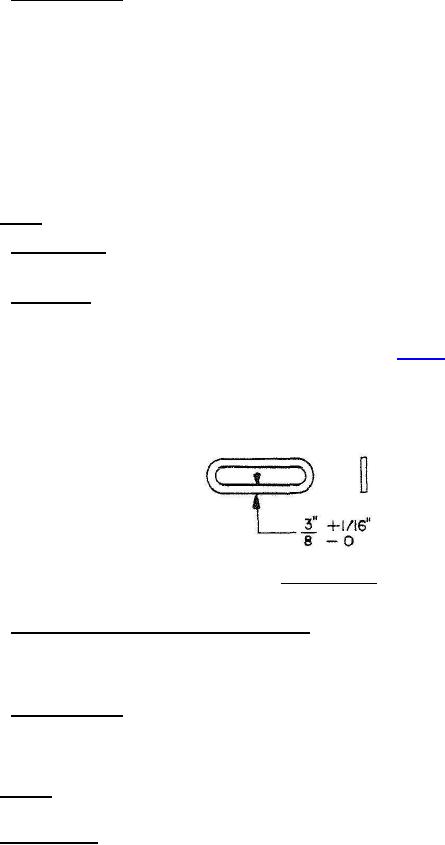

3.12.5.2 Gasket shape. Unless otherwise specified (see 6.2), Class I and II shall be furnished with two identical

gaskets 1/32 inch thick that can be used interchangeably as the steam or water side gasket or the outer side or cover

gasket, and two spacers 1/32 inch by 5/8 inch by 3 inches made of compressed sheet gasket material conforming to

MIL-DTL-24696 Type II. Class I and II gaskets shall be shaped as shown on figure 3. Class IV shall be furnished

with two gaskets, one a steam or water side gasket, one an outer side or cover gasket, and spacers as required to

conform to gauge frame.

FIGURE 3. Shape of gasket.

3.12.5.3 Outside dimensions and bearing surface of gasket. The outside dimensions of Class I and II gaskets

shall be the same as those of the glass for which they are intended. The bearing surface of the gaskets shall be of

uniform width and shall be not less than 3/8 inch and not more than 7/16 inch. The bearing surface and dimensions of

Class IV gaskets shall be in accordance with H6685-798-5483.

3.12.5.4 Simulative service. When tested as specified in 4.7.7.9, the gaskets shall permit no leakage.

Simulative service testing is not required for Class I glass sets using standard reinforced graphite gaskets installed in

gauges with conventional flat gasket seating surfaces. Gauges using special design seating surfaces (grooved,

tapered, curved, or with more than Ra = 400 finish) will require testing.

3.12.6 Rotation. For purposes of positioning during installation, the gauge frame shall be rotated through

360 degrees.

3.12.7 Frame clamping. Individual means of clamping the body and covers shall be used, compensating for

slight buckling or other imperfections throughout the body and cover depth. This shall include individual clamps or

fingers, spring cone washers, studs, through bolts, and shouldered cap screws.

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business