MIL-DTL-16356E

3.9.4 Insert recesses. For Type A and B and Class I and II gauges, recesses for the glasses in the frame bodies

and covers shall not exceed the maximum dimensions of the glass (see 3.12.3.1 and 3.13.1.1) by more than 1/32 inch

on the width and 1/16 inch on the length. The minimum width and length of the recesses shall be such that a glass

having maximum dimensions as specified herein shall be easily inserted. Chambers or frames and covers for all

Type A and B gauges shall be such that if a glass of minimum thickness specified in 3.12.3.1 and 3.13.1.1 as

applicable is clamped into place in the gauge without gaskets and mica shields, the clearance between the surfaces of

the covers and frame body, parallel to the faces of the glass, shall be not less than 1/16 inch. Joint faces for the glasses

in frame bodies and covers shall be finished machined surfaces.

3.9.5 Chamber passage. Steam and water passages of the gauge shall have a clear opening of an area not less

than that of a 3/8 inch diameter circle. This passage shall produce a pressure drop of less than 3 inches of water under

service flow conditions.

3.9.6 Joints. The joints between the glasses and the frame body and between the glasses and the covers shall be

fitted with gaskets. Spacers as necessary shall be used to centralize the glass in the body recesses.

3.9.7 Cover-plates (covers). Vertical movement of the cover with respect to the frame shall be limited (such

that the weight of the cover does not bear on the glass). The covers shall be stiffened or reinforced to withstand

imposed stresses as necessary.

3.10 Gauge fittings and valves.

3.10.1 Nipples and gauge connectors. The frame body or bodies of the gauges shall have a minimum of ¾ inch

outside diameter tubular connecting pieces (nipples, tube assemblies, stems) and shall be made of carbon steel at

least equal to or better than that used for the frame. The connecting piece shall connect the frame body assembly to

the top and bottom flanges. The length of the connecting tubes shall be made to suit the distance between centers of

the top and bottom fittings as installed on the boiler. The required ball-check feature (see 3.10.4) of the bottom

fitting shall be incorporated into a bottom gauge connector or fitting.

3.10.2 Top and bottom shut-off valves. Centers of the top and bottom shut-off valves of the gauges shall be in

the same vertical centerline. Each top and bottom fitting shall include a shut-off valve to be manipulated by a chain

operating a sprocket wheel. Valves shall not back off or drift open at pressures for which rated. Maximum

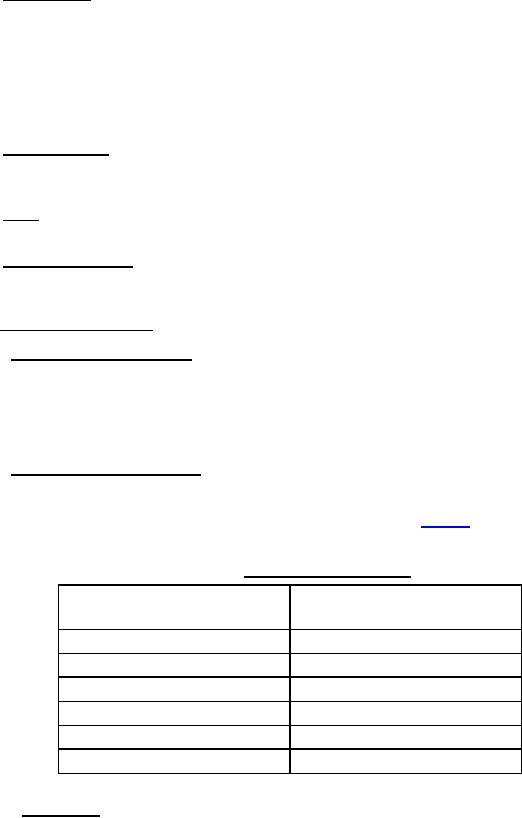

allowable torque to seat valves under all conditions shall be limited as shown in table III.

TABLE III. Maximum allowable torque.

Sprocket Wheel or Hand

Equivalent Torque Tolerance

Wheel Diameter (inches)

±5 Foot-Pounds

7

35

8

41

9

48

10

54

11

61

12

68

3.10.2.1 Chain length. A minimum of 40 feet of chain shall be furnished with each Type A gauge used on

main propulsion boilers. Chain requirements for other applications shall be as specified (see 6.2). Plug cocks shall

not be acceptable as shut off valves for any type gauge. Minimum valve size shall be 3/8 inch. Carbon steel valves in

accordance with ASTM A105/A105M, or Grade WCB of ASTM A216/A216M, shall be acceptable for pressure

ratings, body, and bonnet.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business